| Summary: |

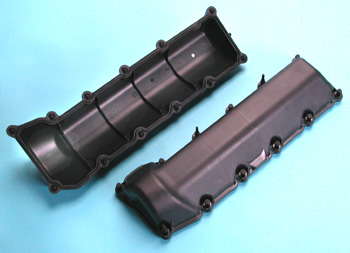

Production of valve cover in plastic without use of a

prototype, resulting in much faster program and largest powertain savings

at DaimlerChrysler of $10 per vehicle. |

| Most Innovative Feature: |

Replacement of magnesium with plastic without the use of a

prototype. |

| Other Innovative Features: |

Program that usually take 18-24 months was done in less

than 12 months. Largest savings to date in ($10) powertrain realized by

DaimlerChrysler. |

| What Forming Process? |

Injection. |

| First Time Process Used: |

No - but first time at this low of a thickness (2.5mm). |

| Previous Process: |

Magnesium - Injection. |

| Tooling Innovations: |

N/A. |

| New Material Developments: |

N/A. |

| Weight Savings: |

Weight was +0.5 lbs from magnesium. |

| Cost Savings: |

$10 per vehicle, which does not include tool life savings.

Largest savings in powertrain at Chrysler. |

| Cost Avoidance: |

Tool life will go to end of project. Magnesium required new

tool every 150,000 parts. No post molding operations needed. Magnesium

required glass beading |

| Direct Consumer Benefit: |

Reduced noise by 1DB. |

| Translates to Other Vehicles?: |

Yes. Program so successful another valve cover being

switched from stamped steel. Others are being looked at. |

| Safety Benefits: |

Thermoset does not burn like magnesium. |

| Environmental Benefits: |

Eliminated EPA glue issue. |

| Additional Comments: |

This program was a huge success at DaimlerChrysler. To

insure that no prototyping was needed computer simulation was used for

mold filling, structural and moldal analysis. Later analysis showed that

these analyses were extremely accurate and proved extremely valuable. |