| Summary: |

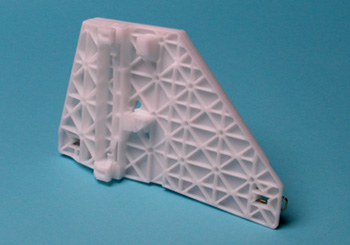

First current production direct replacement of stamped

steel by plastic for a window lifter plate. Significant cost savings

(amount is confidential). |

| Most Innovative Feature: |

Direct Metal (stamped Steel) to Plastic Conversion of the

Lifter Plate (this is part of the window regulator). |

| Other Innovative Features: |

Part manufacturing process reduced from a 3 step process (1

Stamp steel part produced, then 2 acetal overmouldings added to this part)

to a shoot and ship part. |

| What Forming Process? |

Injection Molding |

| First Time Process Used: |

No, but it is the first this large and the first to

directly replace metal in current production. |

| Previous Process: |

Steel Stamping was manufactured, shipped to Injection

molder, then stamping is handloaded into Injection Molding machine and

overmolded with 2 separate moldings added to complete part. |

| Tooling Innovations: |

N/A. |

| New Material Developments: |

N/A. |

| Weight Savings: |

48% |

| Cost Savings: |

Significant Cost Savings, this number is considered

confidential |

| Cost Avoidance: |

No Stamping tooling required, 3 stage process to shoot and

ship part. |

| Direct Consumer Benefit: |

N/A. |

| Translates to Other Vehicles?: |

The concept can be applied, dependent on the door

environment |

| Safety Benefits: |

N/A. |

| Environmental Benefits: |

The lifter plate can be recycled as it is all plastic,

previous process was a galvanized sheet metal. |

| Additional Comments: |

None. |